safety. And that’s fair — safety is the foundation. But the same data that helps identify operational risks can also uncover opportunities to improve efficiency, reduce wear, and lower maintenance costs.

In other words, FDM doesn’t just make flying safer — it can make it smarter and more cost-effective.

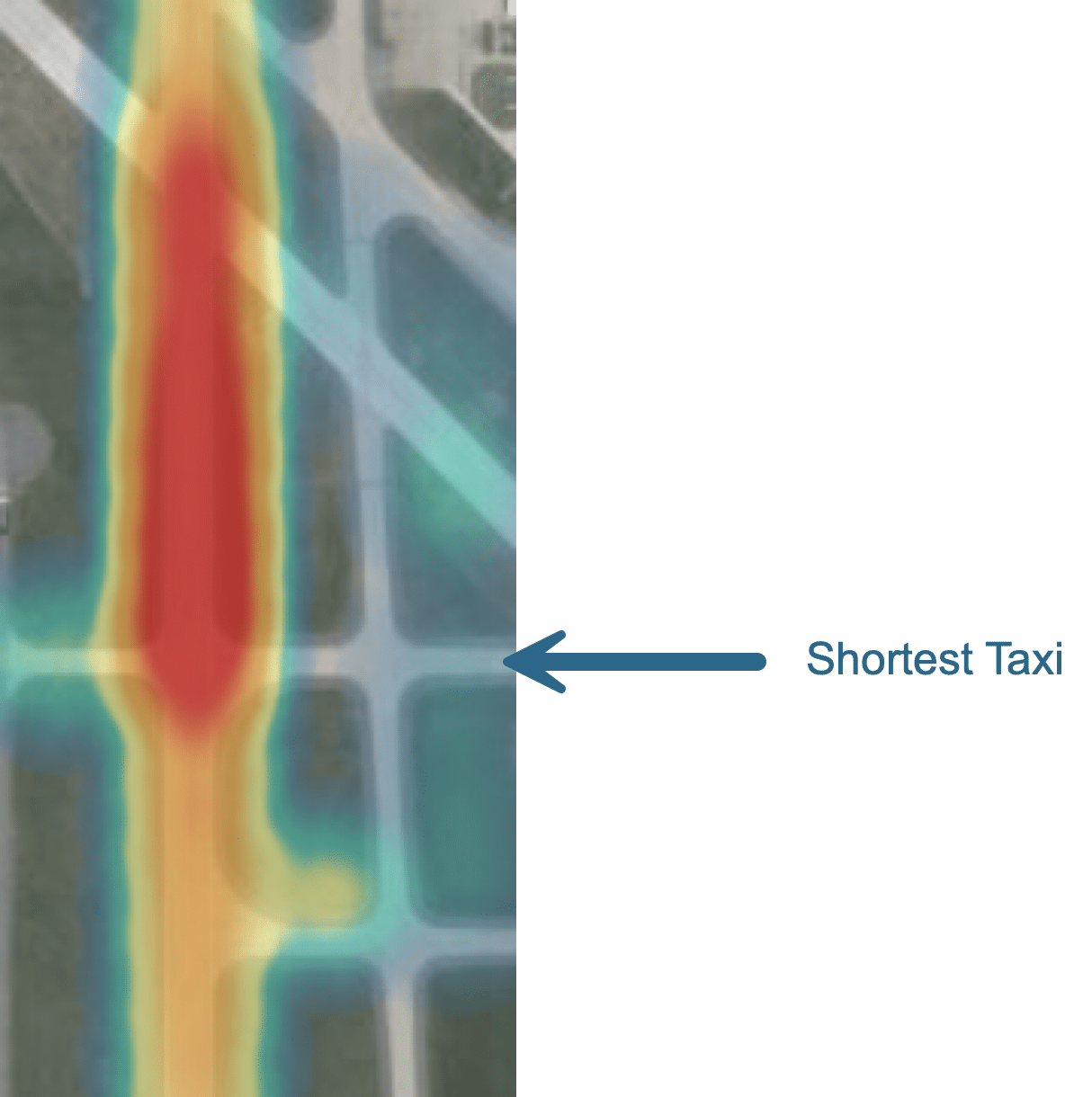

One operator noticed repeated instances of heavy brake applications during landing, but only at certain airports. By reviewing their FDM data, they discovered a clear pattern: some crews were braking aggressively to make an earlier taxiway exit — the one that offered the shortest taxi distance back to the apron.

Armed with this insight, the operator shared the data with their crews and adjusted expectations during arrival. That simple change led to more consistent brake use and reduced wear rates – extending the time between brake servicing.

Brake application during landing rollout. Red indicates heaviest braking.

In another example, an operator using our Engine Condition Trend Reporting (ECTR) service — available as part of our FDM program — identified a shrinking Exhaust Gas Temperature (EGT) margin on one of their Boeing 737s.

Over time, the EGT margin was narrowing, indicating performance degradation. Because the issue was caught early, their maintenance team was able to schedule an inspection and perform corrective work before it became critical.

These are just two examples of how FDM data can deliver financial value well beyond safety. Some of the most common areas where operators see returns include:

-

Fuel efficiency: Identifying non-optimal climb, cruise, or descent profiles.

-

Maintenance planning: Spotting system trends before they trigger alerts.

-

Training focus: Directing simulator or line training toward real-world trends rather than assumptions.

-

Asset health: Helping extend the lifespan of high-value components like brakes, tires, and engines.

Safety may be what brings operators to FDM. But efficiency, predictability, and cost reduction are what keep them invested.

When flight data is analyzed and shared effectively, it empowers operators to make smarter maintenance and operational decisions — protecting both safety and profitability.

Let’s keep in touch

Sign up to get notified of new blog posts, videos or other news and information related to flight data.