(Note: This article was originally published on January 15, 2021).

A few years ago, I posted an article on LinkedIn that gave a glimpse into how data is recovered from damaged flight data recorders. That was around the time of the disappearance of Malaysia Airlines Flight 370, the downing of Malaysia Airlines Flight 17, and the loss of Germanwings Flight 9525.

Unfortunately, the years since I wrote that article have not been without major air accidents. The most notable being the two 737-MAX crashes and, most recently, the loss of the Sriwijaya Air Flight SJ182, a Boeing 737-500.

I’ve read too many accident reports to even try to speculate on what may have happened in some of these accidents – at least in public. I’ve seen too many reports where I thought to myself, “Wow. I didn’t expect THAT to have been the cause.” I was right on a good chunk of them, but some others were just off the charts.

I wait, like everyone else, while the investigators sift through the mountains of information they have to try to piece together what happened.So, I cannot shed any light on the most recent crash, but what I can do is share some insight into how the flight data is typically recovered from the accident recorder so that it can play its part in helping solve the puzzle.

Below are a few pictures from an accident investigation that I participated in in the early 2000’s. This might give you an idea of a typical process of recovering the data from the recorder so that it can be processed in specialized data analysis software.

I do not cover the data analysis part of the investigation, but if you need help with that, let us know – that’s the part Scaled Analytics specializes in and we can certainly help.

In this particular accident, the recorder was recovered from the sea floor a few days after the crash.

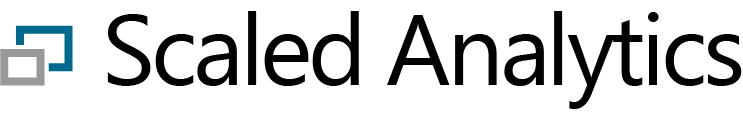

The memory in this recorder is housed in a protective shell as shown in the photo below. The memory itself is encased in a protective foam that helps shield the memory from heat and shock damage.

Below you see the protective foam after it was removed from the metal casing. The electrical lead can be seen coming from the memory still embedded in the foam.

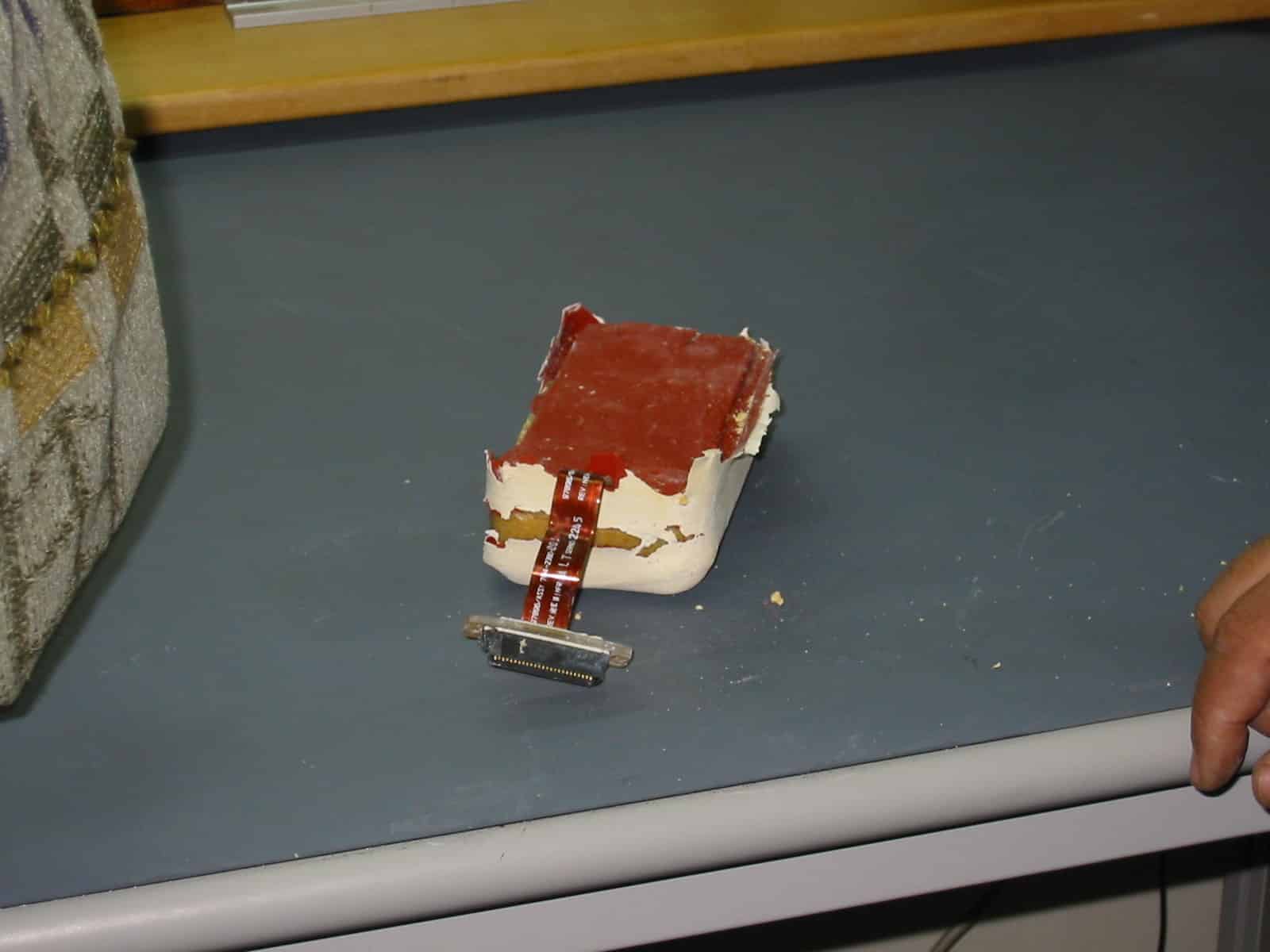

The investigator will then carefully remove the protective foam, revealing the memory card as depicted below.

At the time, I thought one of the more interesting points of data recovery was that the original electrical connector had to be cleanly “cut”. The reason for this is that the original connector could have become damaged. So, the original cable is cut and a new “recovery” cable is connected to a connector opposite the original connector.

You can see the result in the photo below. Note the original cable on the top of the board has been cut (the remaining half is sitting on the table) and the recovery cable has been attached to the bottom of the board.

You can also see the “Bench Unit” flight data recorder in the background of the photo below. This is a fully functioning flight data recorder (whose memory unit has been removed) that will serve as a “surrogate” to allow for the transfer of data from the memory of the crashed recorder to a computer.

Now it is literally just a matter of connecting the memory to the Bench Unit and performing a data download as you normally would with a fully serviceable flight data recorder. The data can then be analyzed in specialized software.

While the process might sound simple on paper, it can be quite a bit of work to get to the memory unit of a damaged recorder. The photo below is the last in the series and illustrates what was left of the recorder once the data was recovered.

It certainly was not as simple as just removing four Phillips screws!

Let’s keep in touch

Sign up to get notified of new blog posts, videos or other news and information related to flight data.